Impressive Info About How To Build A Dyno

A buddy of mine recently sold his chassis dyno.

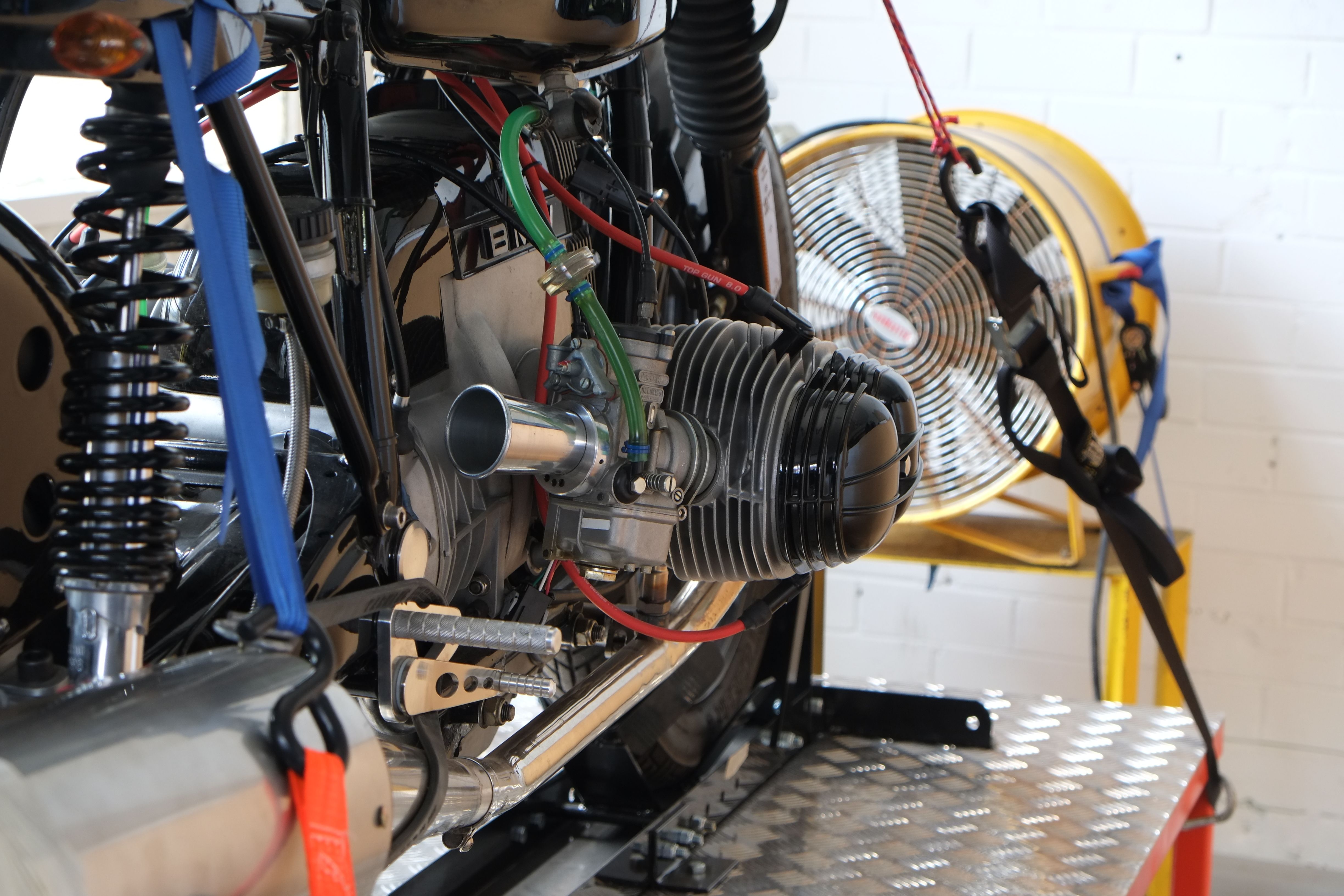

How to build a dyno. I put together a homemade small engine dyno for a diy build, to tune some kart and mini bike engines. Make sure your wiring is sound and that there is no way for an accidental electrocution. I thought a few things were important in.

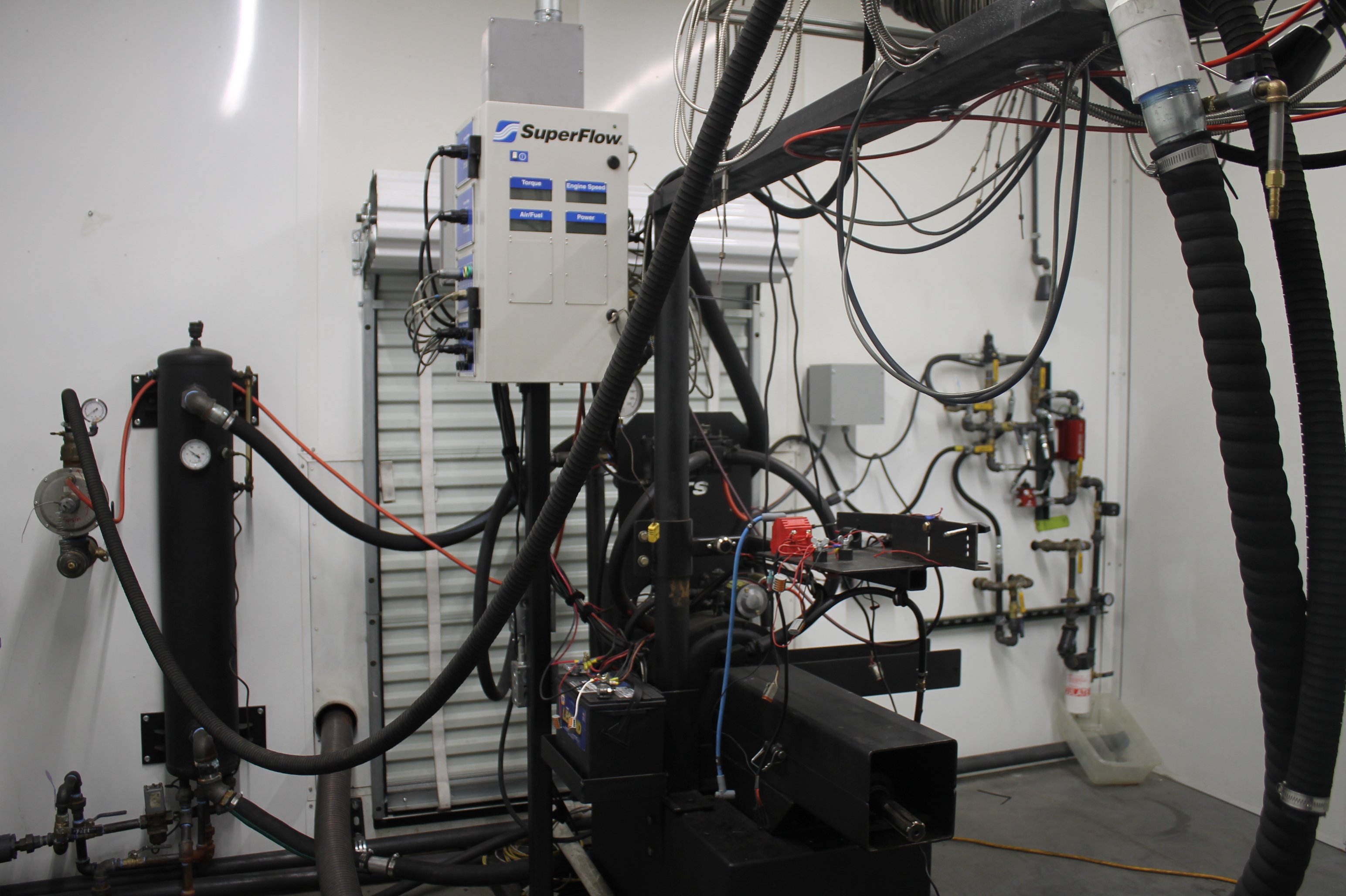

A torque arm is extended from a disk brake caliper and. With the combination of high mechanical stress, heat, and flammable fluids all in the mix, a proper fire suppression system is vitally important when building a dyno. Building the chassis dyno.

The steady state test will give a different number. I've had the opportunity to work in quite a few dyno rooms during my life. When i decided to build the one for current hobby shop, there were a number of things that were necessities.

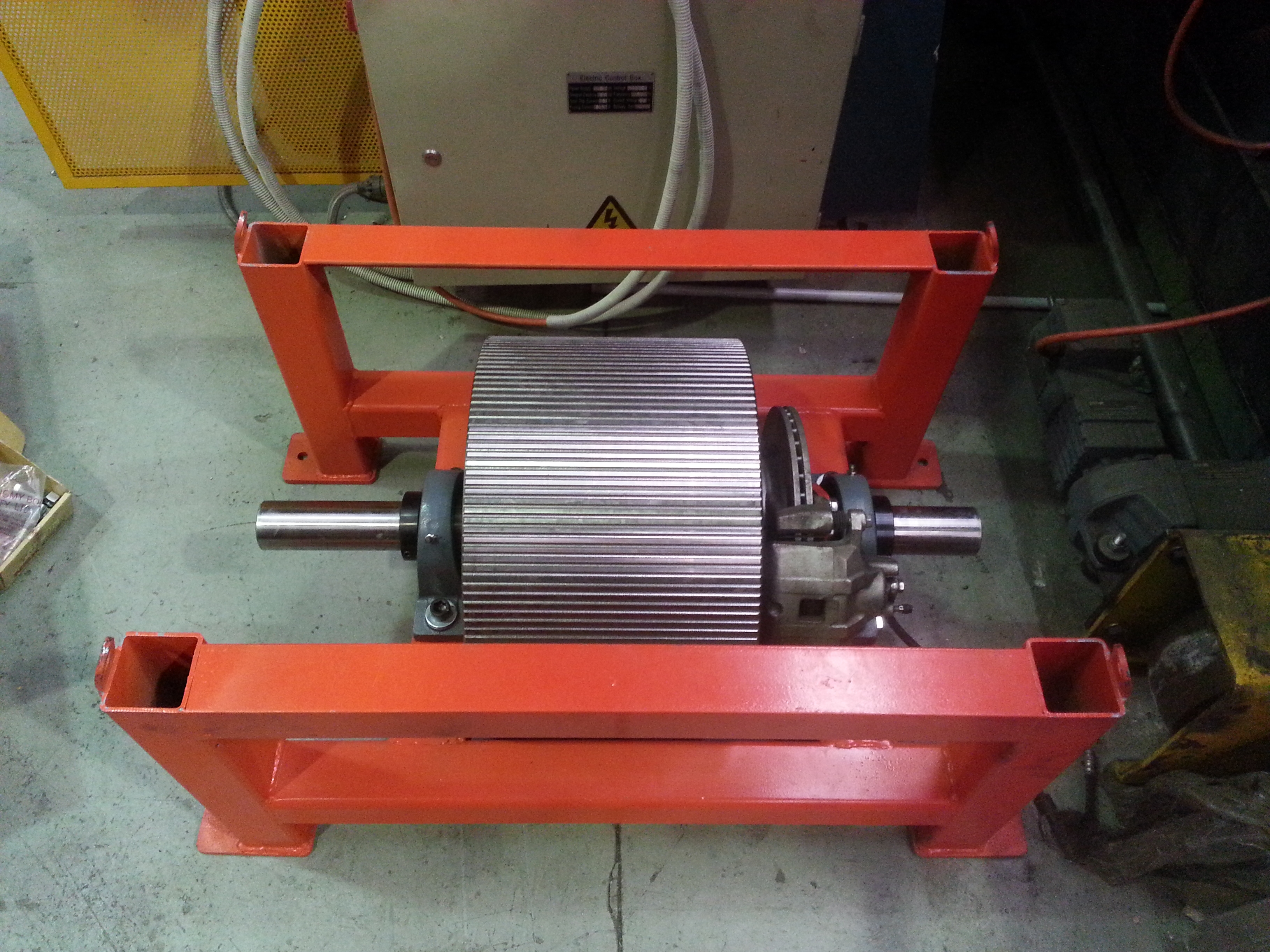

Afterwards we started talking about him building a dyno to replace it. The frame is made from 75x75x6 box section and will be eventually bolted to the floor. Building our dyno room.

Build a shock dyno. The deck is 5mm aluminium chequerplate. The dyno that [jimbo] has built is a prony dyno, and it’s among the oldest and simplest designs available.

Testing with your exhaust system will deliver a more accurate tune and will. Most acceleration tests are 300 or 600 rpm stepped tests. I have now improved the instrumentation and sell the kit through my.

Video describes the build to date and future plans for this build and upcoming video content com. Build your own shock dyno! So gary bought a stuska dyno and its accompanying software, and constructed a dyno cell and a building on his property to house it.

I had a 5 hp 3 ph electric motor which determined. The question is though if it is needed. For about as much as you’ll pay for a shock absorber, you can build your own shock dyno to test it sleepy gomez writer jun 1,.

As far as ignition timing is concerned (which would be the primary reason to tune on a dyno), most are at the maximum advance around 3000 rpm or so. 0:00 / 9:21 i've had a lot of enquiries about how i built this dyno, so thought i'd put up a short clip showing the basics. A bracket for the brake calliper was fabricated and the pillow block bearings are standard 60mm uc212 units.

As you prepare for an engine dyno test, consider that our setup can support full exhaust systems. I wanted a shock dyno to help improve motorcycle front forks and rear suspension units for classic racing. Subscribe to see how i'm breaking it in with futures vi.